Prepare for the smart print factory

INDUSTRY 4.0: THE SMART PRINT FACTORY

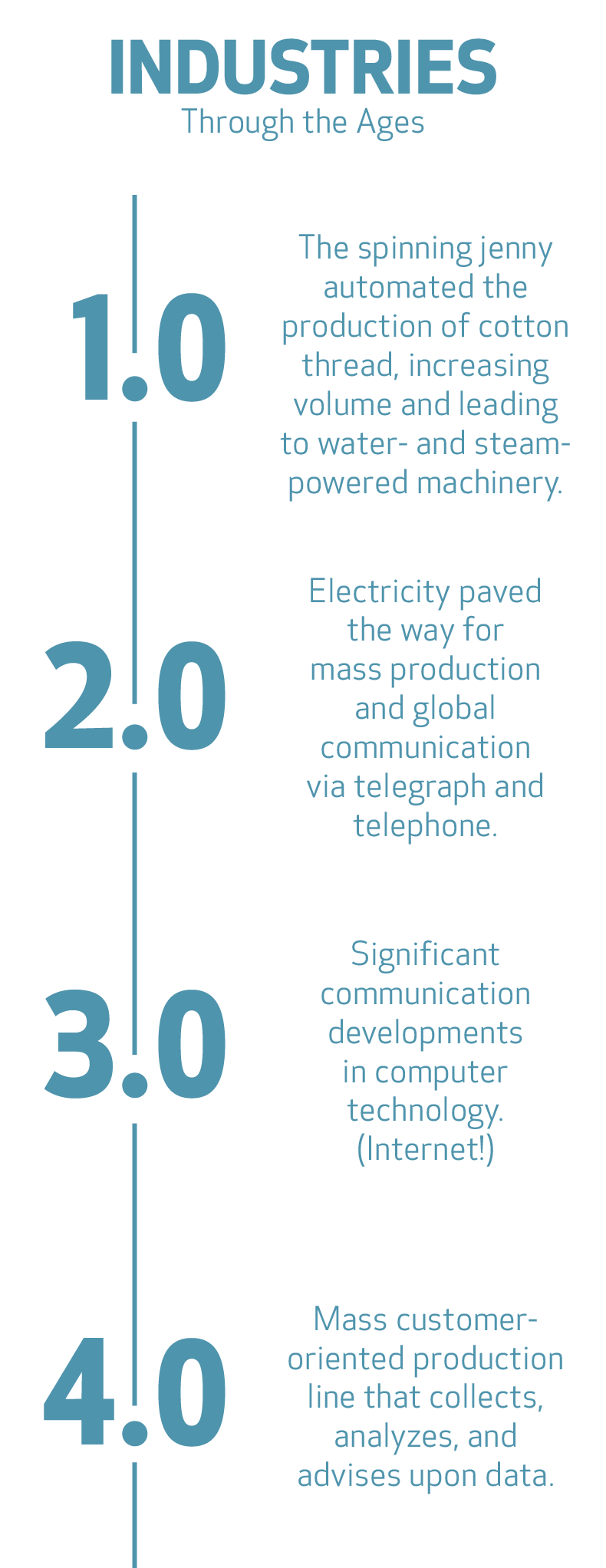

There’s no doubt that the printing industry is going through a change. What was once a craft-based business is now moving to a widely connected and process-driven industry that is paving the way for Industry 4.0. The transition isn’t entirely new, as three previous industrial revolutions changed the way the world conducts business.

How we got here

It all started with mechanization: in the mid-eighteenth century, the spinning jenny helped to automate the production of cotton thread, increasing overall volume and leading to the water- and steam-powered machinery that changed production processes across all industries. This is called Industry 1.0. Once electricity came into the picture, companies were able to introduce mass production and global communication via telegraph and telephone, creating Industry 2.0. The most recent stage, Industry 3.0, resulted from the major development of computing, information, and communications technologies that has increased global connectivity and data collecting capabilities. What Industry 4.0 establishes is the creation of a mass customer-oriented production line that can collect, analyze, and advise upon data.

Companies across the spectrum have already started to implement Industry 4.0, just in ad hoc ways. Most have been held back by outdated business models and technology, but 30 percent of manufacturers that invest in digital transformation by 2018 will be able to maximize outcomes.1

Print service providers can take advantage of elements such as cloud computing, big data, the Industrial Internet of Things, and autonomous robotics to become a smart print factory. Ultimately, every stage of the workflow will unify for a smooth-running operation: more than one billion connected objects will equip factories by 2020, a growth of more than 55 percent of where the industry is now.2 Print providers that do not work to unify their workflows, therefore, risk trailing behind the competition.

Print for the future

New advances in technology are paving the way for print providers to make the transition. One of these technologies is augmented reality for predictive service. This technology incorporates the service engineers’ environment into an immersive virtual world via cell phone, an immersive headset, or Google Glass.™ Service personnel that use this technology have access to knowledge that enables them to hone their skills for faster resolution, reduced downtime, and improved printer performance.

Another innovative technology for print service providers is cobots. These collaborative robots, as the name suggests, help to streamline processes by performing minor print operations such as retrieving and loading a new paper roll into the press, freeing operators to focus on more skillful parts of the workflow. Adding this type of automation can help to speed up production time.

“Our goal… is to ensure our customers perform in the most efficient manner possible…”

Keeping pace

Adopting the technologies of Industry 4.0 is an investment, but print providers already perform some of the functions of a smart print factory today. Data, an essential component for Industry 4.0, plays an important role in modern printing. Keeping pace with frequent short print runs, understanding the impact of time-lapse on workflows, and improving efficiency are made possible through data analytics.

Today’s print providers have adopted: webshops for frequent job submission, chatbots to improve customer interactions, automated workflows for faster print production, and dashboards to closely monitor every step of production; these all feed into the future of the industry. By continuing to analyze efficiency, consumption, and peak production cycles, print providers can begin to establish predictive workflows, implement preventative service, work to solve the ever-changing demands of customer expectations, and move one step closer to becoming smart print factories.

Next steps

Much like Industries 1.0–3.0, the full transition to a smart print factory will not happen overnight. Companies will need to construct a strategy to successfully optimize productivity, resources, cost of operations, and service capabilities. The key to forming a solid strategy is finding the right partner.

At Canon Solutions America, we can help you to develop your approach to this global change. We know that data is vital, but finding the right tools to help analyze that data and streamline workflows can make the difference between staying ahead of the pack and falling behind. “Our goal at Canon Solutions America,” says Jane Nerf, senior product marketing specialist, “is to ensure our customers perform in the most efficient manner possible—whether through automation, the latest technologies, or putting relevant data in their hands—so they can make informed decisions and drive toward their operational efficiencies and overall corporate strategies.”

A new age of digitization and automation is here, and the question is: Are you ready?

1“IDC FutureScape: Worldwide Manufacturing 2017 Predictions,” IDC.

2BI Intelligence 2015, GE 2014.